Woeste 2006 Wood Bits Nonstructural Plan Review of Post-frame Buildings Building Safety Journal

About 45% of residential field inspections result in a code violation. That's co-ordinate to the Common Code Violations survey released in 2013 by the International Code Council (ICC) and the National Association of Homebuilders (NAHB). Researchers polled code officials across the U.South. about the items most probable to be flagged during structure. The survey found overall compliance improving. Although inspectors are flagging a few specific items—well-nigh notably guardrails, stairs and anchor bolts for foundations—more than often than in the past, in full general they reported far fewer failed inspections than in a similar survey published in 2006.

Competitive pressures take certainly contributed to that comeback; failed inspections and re-do's cost fourth dimension and money. Only state-mandated contractor training has also played a role. "The educational requirements for licensing have helped a lot," Vaughn Wicker, ICC's vice president of government relations, said. "A lot of states now require training to get or go on a license, so builders in general have better lawmaking knowledge than in the by."

But fifty-fifty though things are getting better, 45% is yet a big number, leaving plenty of room for improvement. With that in mind, JLC looked at published lists of the height code violations from various municipalities across the state and contacted building inspectors to find out what items have been giving builders the most trouble. Our findings confirmed those of the ICC and NAHB researchers.

Hither is a list of the most common reasons that a builder or remodeler will neglect inspection. Paying extra attending to them should make for fewer items that demand correction.

one. Missing Documentation

The most common reason a builder fails an inspection is the simplest (and to the lowest degree expensive) to remedy: not having all the required documents on site. This was at the meridian of almost every municipal listing we looked at and cited by every code official we contacted.

"The outset affair I look for is the documentation," Glenn Mathewson, a Westminster, Colo. edifice official and a regular JLC contributor, said. "If I show upwardly and they don't have the plans I need for that inspection, so there's no promise of passing." In his city, that includes an engineer's foundation letter, the structural plans, the truss drawings, the plan for the HVAC ductwork and gas piping, and the free energy code documentations. These documents will, of course, vary by jurisdiction, just it's up to the builder to know what they are and to take them available.

Darryl Byle, a former edifice inspector and structural engineer from Kalispell, Mont., said that his city came up with a quick fix for the trouble: The building department decided to put a stop work guild on whatsoever project where the drawings weren't on site. "That got the drawings on site pretty fast," he said.

2. Improperly Placed Ballast Bolts

When it comes to footings and foundations, we expected the biggest offense to be improper rebar placement. We were wrong.

Although some inspectors mentioned rebar, the mistake anybody cited was surprising: missing or improperly placed foundation anchor bolts. The ICC report also listed this equally one of the violations that's get more widespread, though it's not clear why.

A common mistake Byle sees is commodities locations that don't work with the mudsill joints. "You lot need a bolt on each side of every joint on the sill," he said (see "Anchor Bolt Placement," left). "But a lot of concrete guys just put bolts every 6 anxiety, rather than asking the framer where the joints will be." The problem could apparently be avoided past better coordination betwixt the framing crews and the physical crews. Mathewson pointed out that anchor bolts are a lot harder to fix than another problems, then it's worth the try to get them right the first fourth dimension.

It's worth noting, too, that the 2015 IRC now requires the ballast bolts to be placed in the middle third of the width of a foundation plate. This complicates bolt placement even further. For a 2x4 plate, that ways you've merely got about 1 3/16 inches of tolerance to get information technology in the right spot.

3. Braced Wall Errors

Code-mandated braced-wall requirements can be a head-scratcher for someone encountering them for the commencement time. "The requirements are new to a lot of builders and a lot of them are nonetheless climbing the learning curve," Shapiro said. (See "Bracing Walls for Wind," Jul/thirteen.) But even when the bracing requirements are spelled out clearly on the plans, information technology'southward the little details that often escape framers. The most mutual oversight Shapiro finds is missing blocking for braced wall panels. Code requires nailing along all console edges, and that may crave blocking between studs on tall walls or when panels are run horizontally. Fortunately, blocking is usually easy to add.

The trouble Mathewson sees most ofttimes—overdriven nails in bracing panels—tin can take a bit more piece of work to right. "If you lot overdrive a nail, you can reduce the strength of a 7/16-inch panel to that of a 3/viii-inch or 1/4-inch panel," he said. (As an aside, he pointed out that this is a problem with nailing off hangers as well. Overdriving a nail dimples the steel, causing it to lose force.)

4. Weakened Joists and Beams

Inspectors see a lot of beams that aren't sized for the load or that lack proper bearing. This is more common in remodels than in new structure. It often comes up when a contractor cuts through an exterior wall to add a sliding door or removes an interior bearing wall to create a more than open living space. "If it's a load-bearing wall, they oftentimes think they can just open it upward and throw in a double 2x8," Mathewson said. "But y'all need to practice a structural analysis to make up one's mind how much load the beam will need to support, especially if in that location are floors above." He also pointed out that newer homes have more complicated load paths. "You really need to pay attention before y'all get-go poking holes in the structure."

One of the biggest bug Mathewson sees is gaps at the ends of joists or trusses supported by hangers (photo at left). It doesn't take much: Gaps can exist caused by a girder truss that's slightly kleptomaniacal or out of plumb, making the time required to use a cord line and level well spent.

Manufacturers of structural hangers usually specify a maximum gap of 1/8 inch between the stop of the joist and the girder. Anything bigger will put moment arm on the hanger and drastically reduce its load capacity. When hangers are double-shear nailed (toenailed), large gaps go out the nails completely missing the carried member. "People go upset over this because they think I'k existence punitive," he said. "It's not me, it'southward the manufacturer's load requirements."

5. Deck Ledgers and Braces

Byle isn't far from Polson, Mont., where a 2004 deck collapse at a casino injured 52 people afterward the connection between the deck and the building failed. The culprits included hangers that were too small for the joists, improper fastening, and inadequate flashing that set the ledger up for rot.

Despite more attention paid to decks, including the requirement in some jurisdictions for lateral connectors, he and other inspectors still see lots of issues with deck connections. On retrofits, he often recommends that the contractor build a freestanding deck with the deck frame an inch or so away from the house and the structure independently supported on posts . This eliminates the difficulty of properly flashing and fastening the ledger to the firm.

He also finds builders falling downward on deck shear-bracing requirements. Typically, diagonal post bracing is required (photo at right ). To further resist racking, builders can also use flat-framed 2-bys run diagonally on the underside of the joists . "Racking is a source of failure over fourth dimension. If the deck isn't properly braced, fasteners will work loose," Byle said. He added that it doesn't take much: "Something as unproblematic as kids running around and banging into rail tin can put stress on the fasteners."

6. Stair Rise/Run Errors

Rise/run problems can arise where the architect doesn't have enough horizontal space for a planned stairway. Headroom is a limiting factor (see "Stair Layout," beneath), and Byle has seen a lot of builders endeavor to squeeze the stairs in by just pitching the stairway a piddling more steeply, resulting in a rise that may be too loftier or treads that are as well narrow.

Another common problem Byle sees is that builders, who may get the right riser heights and tread depths, often don't accommodate for the added thickness of the flooring at the bottom. That leaves them with a bottom stride that doesn't lucifer the residue of the stairway.

In Hampton, Va., building official Steve Shapiro finds a lot of rise/run errors on stairs leading upward to porches from sidewalks. "I get the impression that people showtime at one cease and work their way up or downwardly," he said. "Then they end up with a top or bottom riser that's likewise short." Some builders may assume that the inspector will overlook this on an exterior stair, but Shapiro pointed out that the riser and tread requirements apply equally to the interior and exterior of a home.

Keep in mind that liability associated with stairs goes beyond inspection failure. Byle, who also works as an expert witness, said that stairs come up upwards again and again in structure litigation cases: "If the stair isn't dimensioned correctly and someone falls, the jury is going to side against the contractor regardless of whether the stair actually caused the fall."

7. Stair Handrails and Guardrails

In some cases, stair handrails and guardrails are the incorrect superlative every bit measured from the tread. By code, they must be a minimum of 34 inches, and no more than 38 inches high. In other cases, the connexion to the stair isn't secure plenty. The latter problem is often because the builder has skimped in the blocking needed to make a secure connection.

Another common oversight is at the return at the acme and lesser of a handrail. The rail can't just end, only has to die back into the wall or post, or stop in a manner the lawmaking calls a safety terminal. Otherwise, the stop of the railing could catch on things similar pants pockets or purse straps, causing a fall. The concluding requirement is relatively new to residential structure but has long been a feature in commercial buildings, where it's meant to protect firefighters in stairwells. "There were cases where a firefighter was running upwardly a stairway with a hose and the hose got caught on the terminate of a handrail, pulling the firefighter downwards," Mathewson said.

Fortunately, stair manufacturers now make a variety of volutes and other termination pieces that make this requirement a lot easier to meet than in the past.

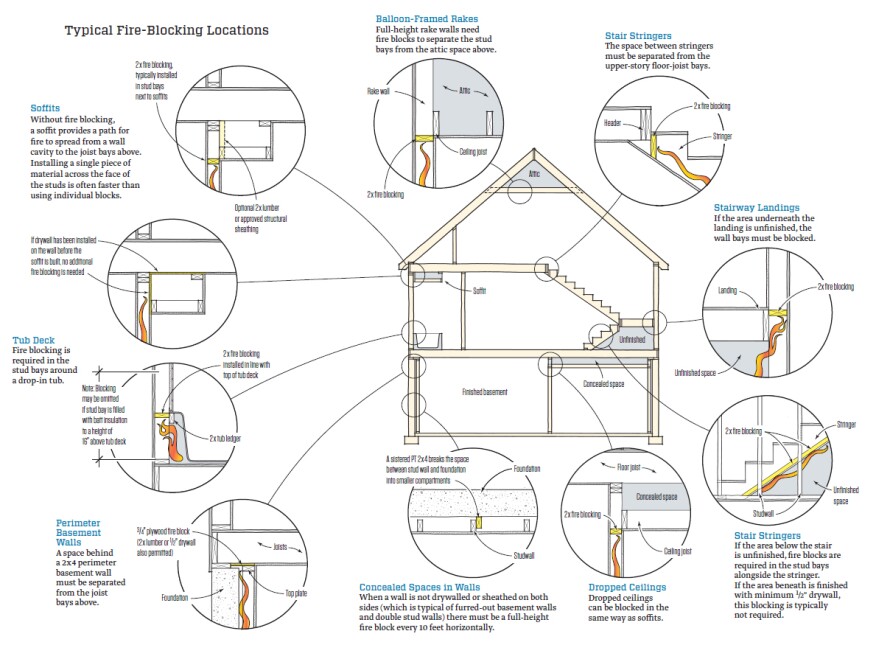

8. Missing or Inadequate Fire Blocking

Fire blocking must be installed at lawmaking-mandated locations in concealed cavities (come across "Typical Fireblocking Locations," side by side page). The blocking prevents these cavities from interim as draft chimneys, thus slowing the spread of flame and smoke during a burn down. This delay buys the occupants time to go out of the house.

Fire blocking must cut off the concealed draft openings between all vertical and horizontal cavities, essentially compartmentalizing the areas from each other. And because they're often obscured by complex elements such as soffits, they're not always obvious, making it piece of cake for the framer to miss spots that need to be blocked. "In my field inspections, I detect that a lot of people autumn down on this," said Aaron Johnson, a Palm Embankment County, Fla., fire inspector who runs a website called TheCodeCoach.com. He added that builders who understand what areas demand to be blocked often use the wrong materials. "One of the about mutual mistakes I see is not using the proper [fire-rated] caulking," he said.

Click here for enlarged version.

Of form as a fire inspector, Johnson would naturally look for blocking issues, but everyone else too cited it every bit 1 of the top reasons for inspection failure. "A day doesn't go by when I don't come across a home with this upshot," Mathewson said.

Oftentimes, a builder will utilise the right material but use it incorrectly, co-ordinate to Mathewson. For instance, some foam sealants are rated for utilize equally fire blocking, but tin only exist installed upward to a maximum thickness, which they're oftentimes non. He besides sees many cases where builders attempt to get away with 7/16-inch OSB as fire blocking, rather than the 23/32 inch required by lawmaking. They usually accept to add together a second layer.

9. Air-Barrier Gaps

With more jurisdictions adopting free energy codes, air-barrier gaps have get an outcome. Equally is the example with burn blocking, these are often in hidden spots, such as behind crash-land-outs for gas fireplaces. "In the old days, the fireplace was but a hole in the wall," Mathewson said. "Now yous have to wrap the thermal envelope effectually the back of it."

He also sees a lot of missing air barriers backside HVAC chases and cranium knee walls. On a knee wall, this can be corrected by putting a rigid cloth similar drywall, OSB or Thermo-Ply on the back of the wall (see "Air-Sealing Articulatio genus Walls," below), but a lot of framers aren't doing it.

Click hither for enlarged version.

The best manner to handle a articulatio genus wall expanse is to move the thermal barrier to the roofline (left) and stand up up the knee walls afterward the ceiling has been drywalled. For production builders who may have less command in scheduling trade partners, the knee wall can serve as the thermal barrier (correct), as long as sheathing is installed on the back side. Also, note the blocking betwixt flooring joists. Without this critical framing addition, ventilation air from roof vents can flow freely though the floor cavity.

10. Exposed Kraft-Faced Insulation

Speaking of knee walls, the bankroll is more than an air barrier; it'southward as well needed to cover kraft-faced insulation batts. These are often left exposed in knee-wall areas and in basements.

Big fault. "You tin can't go out the paper exposed," Mathewson said. In fact you can't even leave a gap betwixt it and the wall covering. "The paper is coated with a bituminous material and is highly flammable," he said. "Y'all don't want airflow over the surface that could feed a fire." The label printed on the insulation clearly states that the facing will burn down and that information technology must exist contact with the wall or ceiling roofing.

That brings united states of america back to the point we made at the starting time of this article: A lot of failed inspections could be avoided if builders really read the manufacturers' instructions and the documentation provided with the edifice permit. The time saved by not doing so can cost a lot more than time later. As Mathewson put it: "It's a lot easier to fix errors with a pencil than with a Sawzall or a sledgehammer."

Source: https://www.jlconline.com/how-to/framing/top-ten-code-violations_o

0 Response to "Woeste 2006 Wood Bits Nonstructural Plan Review of Post-frame Buildings Building Safety Journal"

Post a Comment